-40%

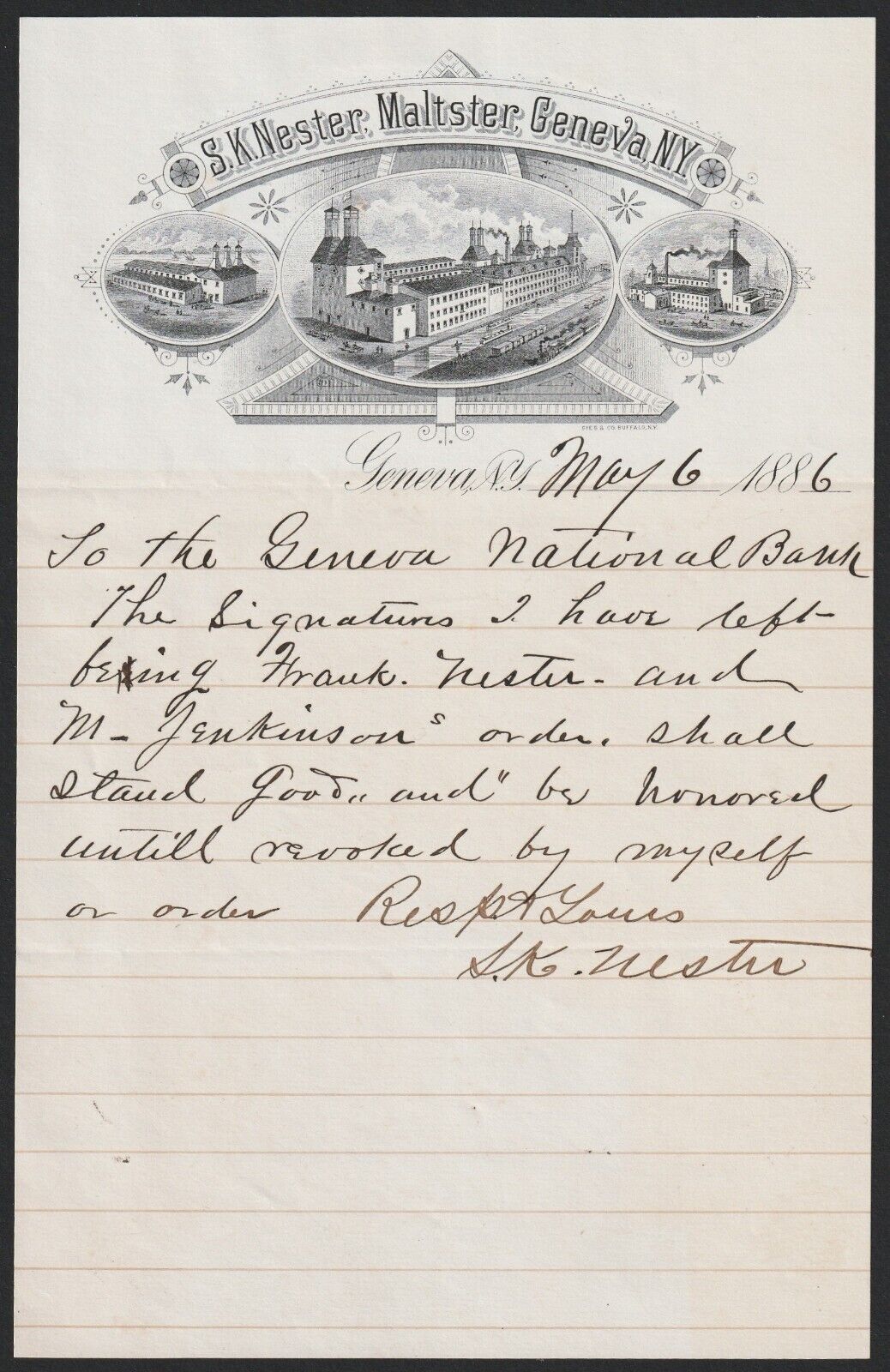

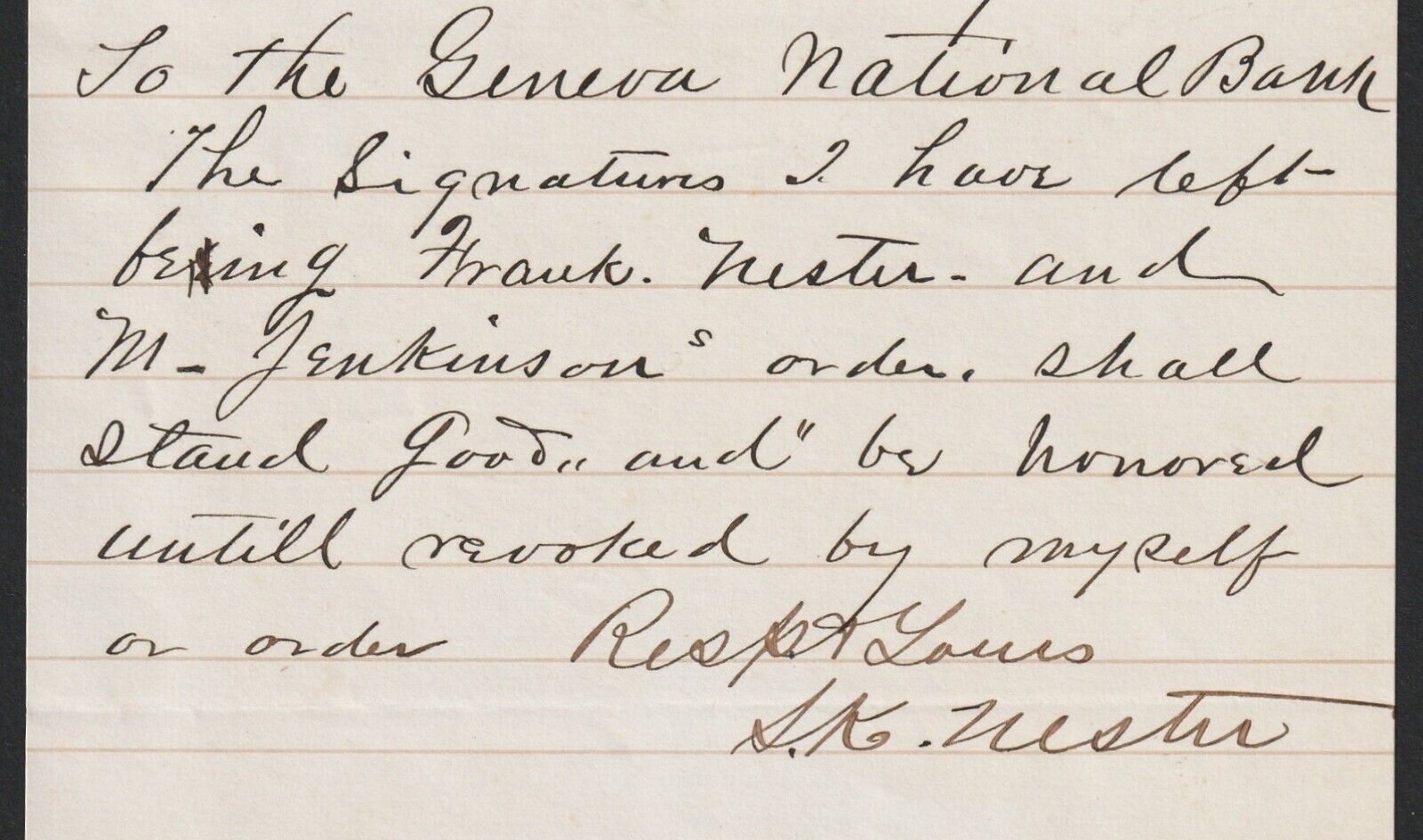

RARE Orig Signed Letter - Samuel K Nester Malster - 1886 Geneva NY Malt Brewery

$ 155.76

- Description

- Size Guide

Description

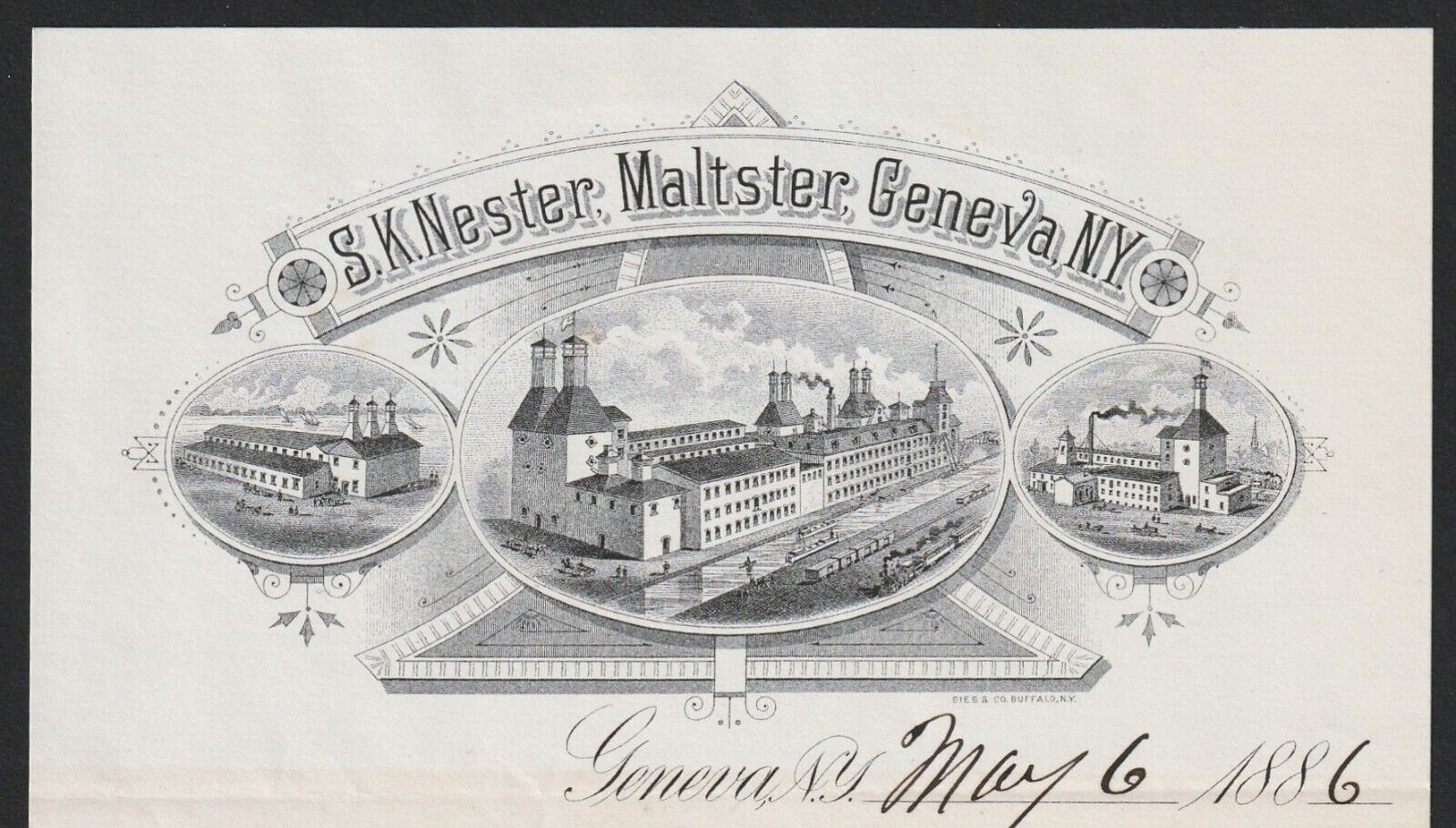

RAREOriginal Letter on Letterhead

Signed - by Maltster - Samuel K. Nester

Geneva, New York

1886

For offer, a nice old letter! Fresh from an old prominent estate in Western NY. Never offered on the market until now.

Vintage, Old, Original -

NOT

a Reproduction - Guaranteed !!

Autograph letter signed - als, by S.K. Nester. Great graphic of factory / building on letterhead. In good to very good condition. Small area of paper remains on back. Please see photos and scans.

If you collect 19th century Americana advertisement ad history, pre prohibition, American printing, etc. this is a nice one for your paper or ephemera collection. Genealogy research importance as well. Combine shipping on multiple bid wins! 2901

Malting is the process of steeping, germinating and drying grain to convert it into malt. The malt is mainly used for brewing or whisky making, but can also be used to make malt vinegar or malt extract. Various grains are used for malting, most often barley, sorghum, wheat or rye.

Several types of equipment can be used to produce the malt. Traditional floor malting germinates the grains in a thin layer on a solid floor, and the grain is manually raked and turned to keep the grains loose and aerated. In a modern malt house the process is more automated, and the grain is germinated on a floor that is slotted to allow air to be forced through the grain bed. Large mechanical turners, e.g., Saladin boxes, keep the much thicker bed loose with higher productivity and better energy efficiency.

Intake

The grain is received at the malt house from the farmer. It is taken in from the field and cleaned (dressed), and dried if necessary, to ensure the grain remains in the best condition to produce good malt. It is tested to check for suitability for malting and to prevent dead or unfit grain from entering the process. Typical quality checks include:

Moisture content

Nitrogen content (total nitrogen)

Percentage of foreign matter

Absence of fungal growth and metabolites

Germinative capacity and germinative energy

Water sensitivity

Drying

Caramel malt

Roasted malt

Bavarian malt varieties for beer

Barley received at the malt house with moisture of more than 13% must be dried before it can be safely stored without loss of germinative capacity. The moisture is removed by circulating heated air (up to 50 °C) through the grain and can either be performed using dedicated grain driers or as a batch process using a kiln. High temperatures or over-drying will damage or kill the barley embryos and the grain will not germinate after steeping. The dry barley can safely be stored for up to 18 months without fungal growth or loss of grain vigour.

Cleaning

The aim of barley cleaning is to remove foreign matter (straw, chaff, dust and thin corns) found in the incoming grain, leaving only the grain most likely to produce a good malt. Magnets are used to remove ferrous metals from the grain, in turn reducing the possibility of sparks, which could lead to a dust explosion. Rotating and shaking sieves are used to remove unwanted foreign matter either larger (straw and un-threshed ears) or smaller (sand and thin corns) than the normal barley grain. During the sieving process an aspiration system removes the dust and chaff. De-stoners or shaking screens are used to separate small stones from the barley. The stones, which are denser than the barley, move out the top of the machine and the cleaned barley exits at the bottom. Half corn separators may be used to remove broken kernels. Half kernels need to be removed as only the one half will germinate and produce enzymes. At the end of the cleaning process the grain is weighed to determine the cleaning losses (the difference between the weight of grain received and the weight of the grain after cleaning) and it is transferred to a silo for storage.

Storage

Grain silos at Port Giles, South Australia

The barley must be safely stored to maintain the grain vigour for germination. Storage at a malt house is normally in vertical silos made of steel or concrete for ease of use, but may be in flat stores when large amounts of grain is to be stored. The grain is stored in a manner that protects it from moisture and pests. A typical silo will store between 5,000 and 20,000 tons of clean dry barley ready for malting.

During storage the temperature of the silo is measured and monitored over time as a temperature increase can indicate insect activity. Additional equipment may be used to keep the grain temperature below 18 °C to inhibit insect growth. Silos are normally fitted with a system for rotating grain from one silo to another to break-up hot spots within the grain. A fumigation system can be used to administer a fumigant (normally phosphine) to the silo.

Wet process

The wet process begins with steeping to get germination started and ends with kilning which removes the moisture and produces a stable final product.[1]

A batch of malt is known as a piece and a piece can be as large as 400 tons. Below a standardised base malt protocol is described:

Steeping

Steeping is the start of the active malting process. Steep water is added to cover the grain and the grain moisture content increases from around 12% to between 40 and 45%. In a modern pneumatic malt house, the grain is alternatively submerged (wet stand) and then drained (an air rest) for two or three cycles to achieve the target grain moisture content and chit count. The first visible sign of germination is the appearance of rootlets known as "chit"; the proportion of chitted grains indicates the progress of the steeping process.

When the grain is immersed in water (known as a "wet stand"), air is bubbled through the slurry of water and grain periodically. The aim of this aeration[2] is to keep the process aerobic to maximize barley growth. Other advantages of the rousing are to get good mixing, to loosen dirt and to even out hydrostatic pressures at the bottom of the steep vessels. (Air flow rate: 1.5m3/ton per hour)[3]

At the end of the wet stand the water is drained out and this is the start of the "air stand" or "air rest". Fans are run to supply fresh air to replenish oxygen and to remove excess carbon dioxide produced by grain respiration. The temperature of the air supplied is important as the grain should be kept between 10 and 15 °C. The aeration requirements (cubic metres per ton per minute) are higher in the second and third air rests as the grain's metabolic activity is higher. (Air flow rate: 300m3/ton per hour).[3]

At the end of steeping the grain is "cast-out" to germination. Cast-out may be done as a slurry during a wet stand or as moist grain during an air rest.

Germination

The aim of germination is to grow the barley grains. This allows the development of malt enzymes, and these enzymes modify the structure of the barley endosperm by breaking down the cell walls and the protein matrix. Germination produces a large amount of heat; if safety precautions are not taken the malt will burn.[4]

A sample of green malt on about day three, with visible malt culms

The enzymes produced during germination are needed to break down the starch for the brewer or distiller during the mashing process.

The grain bed is maintained at a constant temperature of between 10 and 16 °C by the constant supply of fresh humidified air. Turners move through the grain bed to keep it loose to allow for sufficient airflow.

Kilning

Kilning reduces the grain moisture content and stops the germination process.[5] In the first stage, the "free drying stage" the air temperatures are kept cool to dry the grain without causing the enzymes to denature.

As the grain dries it is possible to raise the incoming air temperature for the second stage of forced drying to further dry the grain; the target malt moisture after kilning is around 5% by weight. During forced drying the relative humidity of the air coming from the bed drops, and the maltster is able to use a portion of the warm air as return air.

During the last few hours of kilning the air temperature is raised to above 80 °C (the "curing stage") to break SMM down to DMS to reduce the DMS potential of the malt. DMS is an off flavour that tastes like sweetcorn in the final beer. The high temperatures of kilning also produce the colour in the malt through the Maillard reaction.

Finally the kilned malt is cooled before the kiln is stripped (emptied).

Deculming

The rootlets of the malt (also known as culms) are removed[clarification needed] from the malt soon after transfer from the kiln. The removed culms are sold or processed as animal feed.[6]

The cleaned malt is stored in silos to be blended with similar malt pieces to produce larger homogenous batches of malt.

Malt cleaning

Finally the malt is cleaned prior to sale using sieves and aspiration to remove the dust, lumps and stones in the malt. Magnets are used to remove any steel that might damage the mill rollers.

Malt is germinated cereal grain that has been dried in a process known as "malting". The grain is made to germinate by soaking in water and is then halted from germinating further by drying with hot air.[1][2][3][4] Malted grain is used to make beer, whisky, malted milk, malt vinegar, confections such as Maltesers and Whoppers, flavored drinks such as Horlicks, Ovaltine, and Milo, and some baked goods, such as malt loaf, bagels, and Rich Tea biscuits. Malted grain that has been ground into a coarse meal is known as "sweet meal".[5][6]

Malting grain develops the enzymes (α-amylase, β-amylase) required for modifying the grains' starches into various types of sugar, including monosaccharide glucose, disaccharide maltose, trisaccharide maltotriose, and higher sugars called maltodextrines. It also develops other enzymes, such as proteases, that break down the proteins in the grain into forms that can be used by yeast. The point at which the malting process is stopped affects the starch-to-enzyme ratio, and partly converted starch becomes fermentable sugars. Malt also contains small amounts of other sugars, such as sucrose and fructose, which are not products of starch modification, but which are already in the grain. Further conversion to fermentable sugars is achieved during the mashing process.

Various cereals are malted, though barley is the most common. A high-protein form of malted barley is often a label-listed ingredient in blended flours typically used in the manufacture of yeast bread and other baked goods.[7] The term "malt" refers to several products of the process: the grains to which this process has been applied, for example, malted barley; the sugar, heavy in maltose, derived from such grains, such as the baker's malt used in various cereals; or a product based on malted milk, similar to a malted milkshake (i.e. "malts").

Malt beer is a sweet, low-alcohol beer (0–2.5% ABV[1]) that is brewed like regular beer but with low or minimal fermentation. To keep the alcohol content low, one of two methods may be used: either the yeast is added at about 0 °C (resulting in an alcohol content of under 0.5% ABV) or fermentation is halted at the desired alcohol content (usually in the range of 1 to 2% ABV). It is made from barley malt syrup, sugar, yeast, hops, and water.[2]

Malt beer is considered to be nutritious and is sometimes given to nursing mothers.[3] Among the ancient Egyptians, their form of malt beer (zythum) was considered to work as both a laxative and antidiarrheal; it was considered dangerous, however, for the sick or pregnant to drink it.

Malt beer is sometimes called "malta" or "wheat soda", but that term is properly[weasel words] reserved for the non-alcoholic but similarly tasting soft drink. Several brands popularly referred to as Malzbier in Germany, Austria and Switzerland are actually types of Malta.[4] The same is true for such Danish brands as Tuborg Supermalt and Powermalt.[citation needed] In the United Kingdom, Danish malt drinks have become popular amongst the South Asian community and have been sold in their dedicated supermarkets since the 1970s.

After soft drinks, malt beer is one of the most popular beverages sold in Iceland. The two main brands are Egils Maltextrakt (1.2% ABV) and Víking Maltöl (0.9% ABV).[5] Additionally, a seasonal hvítöl is available in the Christmas month (2.2% ABV).[6] The Icelandic malt beer was modelled on the Danish maltøl, which is still brewed by at least one company in Denmark.[7]

In Southern Brazil, with its large communities of German immigrants, a brand called Brahma Malzbier is very popular and it is mainly consumed during the winter months.

In Israel, brands include Nesher Malt, Malt Star and Malti.[8]

Varieties of malt beer are also popular in some Caribbean countries.

West African brands include Guinness Malt, Amstel Malt, Maltex, and Malteni. These are sold as energy drinks.

Geneva is a city in Ontario and Seneca counties in the U.S. state of New York. It is at the northern end of Seneca Lake; all land portions of the city are within Ontario County; the water portions are in Seneca County. The population was 13,261 at the 2010 census.[2] The city is supposedly named after the city and canton of Geneva in Switzerland.[3] The main settlement of the Seneca was spelled Zoneshio by early white settlers, and was described as being two miles north of Seneca Lake.[4]

The city borders and was once (the portion in Ontario County) part of the Town of Geneva. The city identifies as the "Lake Trout Capital of the World."[5]

The area was long occupied by the Seneca tribe, which had established a major village of Kanadaseaga here by 1687.[6] The British helped fortify the village against the French of Canada during the Seven Years' War (locally known as the French and Indian War); later they added defensive fortifications against the Americans during the Revolutionary War. During the latter warfare, the punitive Sullivan Expedition of 1779 mounted by rebel forces destroyed many of the dwellings, as well as the winter stores of the people, and they abandoned the ruins. Following the war and the forced removal of the Seneca from their native land, European-Americans settled here about 1793. They developed a town encouraged by the Pulteney Association, which owned the land and was selling plots.

At the end of the Revolutionary War, Lt. Col. Seth Reed (né Read), who had fought at Bunker Hill, was one of many pioneers who moved from Massachusetts into Ontario County. By trade with the Seneca, he bought a tract of land eighteen miles in extent. (This was illegal, as only the US government was authorized to make land deals with the Native Americans.) This occurred in 1787, while his wife Hannah stayed in Uxbridge, Massachusetts with their family.[7] "Seth Read moved his wife Hannah and their family to Geneva, Ontario County, New York in the winter of 1790".[8]

The settlement at Geneva was not yet permanent; the European Americans continued to harass the Seneca on the frontier. In 1795 Read and his family removed to Erie, Pennsylvania, where they became the earliest European-American settlers.[9]

The "Village of Geneva" was incorporated in 1806, formally separating it from the surrounding area of Geneva Town. Later the village became a city through a 1871 charter.[10]

In the 1830s, a government surveyor named John Brink named both Geneva Lake and Lake Geneva in Wisconsin after Geneva, New York. Geneva, Nebraska, founded in 1871, is considered to have been named after the one in New York, rather than directly for the Swiss city.

Nearby :

Towns

Covert

Fayette

Junius

Lodi

Ovid

Romulus

Seneca Falls

Tyre

Varick

Waterloo

Hamlets

Seneca county has a number of unincorporated communities. Most are considered hamlets.

Border City

Bridgeport

Canoga

Caywood

Covert

Dobbins Corner

Dublin

East Geneva

East Varick

Fayette

Kendaia

MacDougall

Magee

Malcom

Mays Point

Townsendville

Tyre

Varick

Willard